DLK12M L-5.0-Z

External Diameter:77

Brand:WOK

Place of Origin:China

Number of teeth:54

Machine Type:Electricbicycle

Minimum order quantity:≥2

Product Code:DLK12M

E-mail:wokclutch@aliyun.com

Service hotline+8613506119400

Home > Product > electric bicycle motor clutch > Electric bicycle inner rotor motor clutch

External Diameter:77

Brand:WOK

Place of Origin:China

Number of teeth:54

Machine Type:Electricbicycle

Minimum order quantity:≥2

Product Code:DLK12M

E-mail:wokclutch@aliyun.com

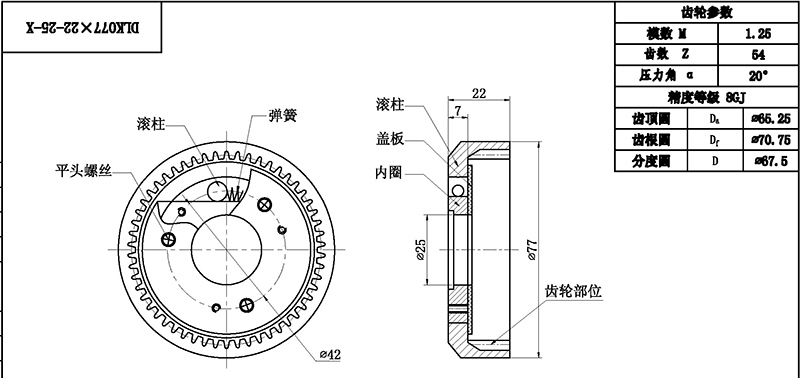

| E-bike Inner Rotor Motor Clutch Technical Specifications Table | ||||||||

| Product Code | external diameter | Addendum diameter | Root circle diameter | Dividing circle diamerer | Number of teeth | Modulus | Pressure angle | Accuracy class |

| DLK077×22-25-X | 77 | 65.25 | 70.75 | 67.5 | 54 | 1.25 | 20° | 8GJ |

| DLK087×20.5-39-X | 87 | 76.3 | 81.1 | 78 | 78 | 1 | 20° | 8GJ |

| DLK94-Z63 | 94 | 61 | 65.5 | 63 | 63 | 1 | 20° | 8EG/GB1095 |

| DLK98-Z54 | 98 | 65.35 | 70.62 | 54 | 1.25 | 20° | GB10095-888GJ | |

| DLK99-Z54 | 99 | 65.35 | 70.62 | 54 | 1.25 | 20° | GB10095-888GJ | |

| DLK103.5-Z58 | 103.5 | 70 | 75.625 | 72.5 | 58 | 1.25 | 20° | 8-GB/T10095 |

| DLK110×21.5-40-Z81 | 110 | 98.7 | 104.33 | 101.25 | 81 | 1.25 | 20° | 8/GB10095 |

| DLK116-Z69 | 116 | 83.986 | 89.611 | 69 | 1.25 | 20° | GB10095-888GJ | |

| DLK124-Z60 | 124 | 86.85 | 93.6 | 90 | 60 | 1.5 | 20° | 8EG/GB1095 |

| DLK129-Z75 | 129 | 91.25 | 96.785 | 92.419 | 75 | 1.25 | 20° | JGMA 3 |

| 1. This product is suitable for electric bicycle wheel hub motors( Inner Rotor Motor) 2. DLK077×22-25-X Corresponding product model code: DLK12M L-5.0-Z 20211202 → WOK(right rotation) | ||||||||

Product description

DLK077×22-25-X——This one-way clutch is mainly used in electric bicycles equipped with inner rotor motors, and is independently developed and produced by our company. The dynamic balance effect of using the clutch rotor is better, the use performance of the electric bicycle motor is improved, and it has the advantages of long service life, high temperature resistance, low noise, and more stable performance.

Technical requirements:

1. The clutch can withstand 300,000 clutch experiments without failure, and the torque is between 40-50N; the maximum torque is greater than 180N.m, to ensure that it is normal, and it cannot slip or jam. When the torque reaches 120N.m, the stress point should not have scratches.

Tel