R0102.WOK-190705A1.A2.A3.A4

External Diameter:124

Brand:WOK

Place of Origin:China

Number of teeth:60

Machine Type:Electricbicycle

Minimum order quantity:≥2

Product Code:DLK124-Z60

E-mail:wokclutch@aliyun.com

Service hotline+8613506119400

Home > Product > electric bicycle motor clutch > Electric bicycle inner rotor motor clutch

External Diameter:124

Brand:WOK

Place of Origin:China

Number of teeth:60

Machine Type:Electricbicycle

Minimum order quantity:≥2

Product Code:DLK124-Z60

E-mail:wokclutch@aliyun.com

| E-bike Inner Rotor Motor Clutch Technical Specifications Table | ||||||||

| Product Code | external diameter | Addendum diameter | Root circle diameter | Dividing circle diamerer | Number of teeth | Modulus | Pressure angle | Accuracy class |

| DLK077×22-25-X | 77 | 65.25 | 70.75 | 67.5 | 54 | 1.25 | 20° | 8GJ |

| DLK087×20.5-39-X | 87 | 76.3 | 81.1 | 78 | 78 | 1 | 20° | 8GJ |

| DLK94-Z63 | 94 | 61 | 65.5 | 63 | 63 | 1 | 20° | 8EG/GB1095 |

| DLK98-Z54 | 98 | 65.35 | 70.62 | 54 | 1.25 | 20° | GB10095-888GJ | |

| DLK99-Z54 | 99 | 65.35 | 70.62 | 54 | 1.25 | 20° | GB10095-888GJ | |

| DLK103.5-Z58 | 103.5 | 70 | 75.625 | 72.5 | 58 | 1.25 | 20° | 8-GB/T10095 |

| DLK110×21.5-40-Z81 | 110 | 98.7 | 104.33 | 101.25 | 81 | 1.25 | 20° | 8/GB10095 |

| DLK116-Z69 | 116 | 83.986 | 89.611 | 69 | 1.25 | 20° | GB10095-888GJ | |

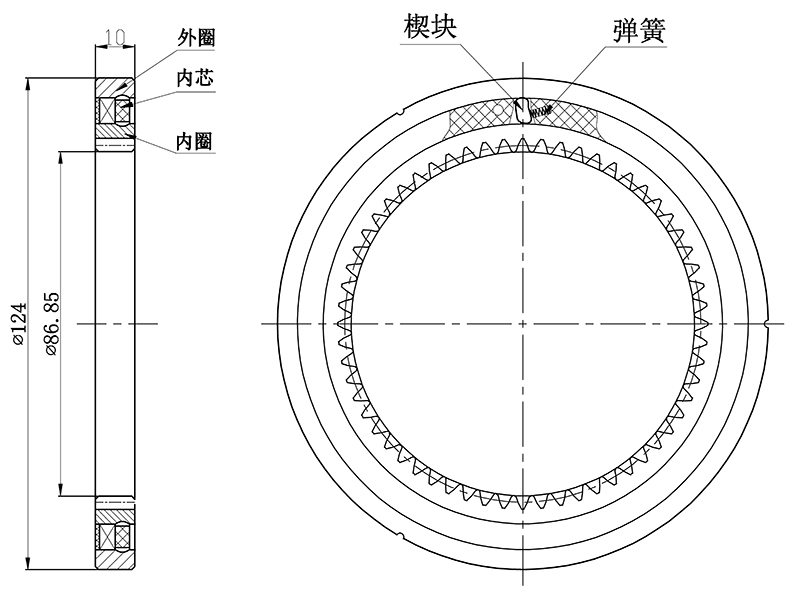

| DLK124-Z60 | 124 | 86.85 | 93.6 | 90 | 60 | 1.5 | 20° | 8EG/GB1095 |

| DLK129-Z75 | 129 | 91.25 | 96.785 | 92.419 | 75 | 1.25 | 20° | JGMA 3 |

| 1. This product is suitable for electric bicycle wheel hub motors( Inner Rotor Motor) 2. DLK124-Z60 Corresponding product model code: R0102.WOK-190705A1.A2.A3.A4 L-4.7-1 ← 31-4(levorotation) | ||||||||

Product description

This one-way clutch is mainly used for electric bicycles equipped with an inner rotor motor, and is independently developed and produced by our company. The use of this clutch rotor has a better dynamic balance effect, improves the performance of electric bicycle motors, and has advantages such as long service life, high temperature resistance, low noise, and more stable performance.

Technical parameter requirements:

1. Use high lubricating grease fillers internally and seal them properly;

2. The parts must be cleaned and cleaned before assembly, without burrs, flash edges, oxide skin, rust, chips, oil stains, colorants, and dust;

3. The rated torque of the one-way clutch is 50N. m, and the maximum torque is greater than 80N. m. It can rotate flexibly when leaving, with more than 300000 clutch times;

4. When the one-way clutch slips, the ball must work. At this time, the concentricity of the inner and outer rings remains within 0.035. When the one-way clutch transfers torque, the ratchet operates. At this time, the concentricity of the inner and outer rings is within 0.045.

Tel